Liquid Nitrogen and Carbon Dioxide can be used interchangeably in many food freezing applications. However, Liquid Nitrogen often offers many advantages over Carbon Dioxide.

| Liquid Nitrogen | Carbon Dioxide | |

| Safety and Environmental Considerations | LN2 is chemically inert. An increase in N2 levels of 2% is not dangerous to humans. LN2 is much easier to exhaust than C02. |

C02 is faintly reactive and toxic. OSHA’s carbon dioxide exposure limit in the breathing atmosphere is just 0.5 percent. If incorrectly sized or operated, dry ice snow may collect on the process room floor. |

| Recommended Safety Equipment | Matheson Tri-Gas recommends an oxygen deficiency monitoring system installed in the processing room for both Liquid Nitrogen and Carbon Dioxide freezing equipment. | Matheson Tri-Gas recommends an oxygen deficiency monitoring system installed in the processing room for both Liquid Nitrogen and Carbon Dioxide freezing equipment. |

| Food Quality | Rapid freezing locks in moisture and preserves texture. | Slower freezing can negatively affect food quality. |

| Investment Cost | Lower freezing temperatures mean quicker freezing so equipment needed to produce same amount of product is smaller. Smaller size equipment means lower cost. | Higher freezing temperatures mean the equipment has to be proportionally larger to achieve the same throughput. |

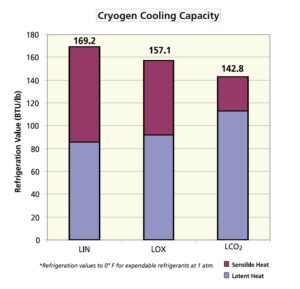

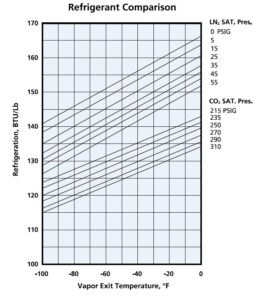

| Operating Cost | LN2 has about an 18% higher refrigeration value (see chart on back) when compared to C02*. Therefore, on a pound per pound basis, the freezing process would use about 18% less LN2 than C02. | Even if LN2 is more expensive than CO2, the price per pound of frozen product can be less using LN2 since the freezing process would use less cryogen. |

| Maintenance Cost | Simple equipment with low maintenance requirements. | Complicated equipment requires more maintenance. |

| Production Rate | Lower operating temperatures and shorter dwell time result in almost twice the throughput in the same footprint. For example, a 20 foot LN2 tunnel can deliver the same output as a 30 foot CO2 tunnel | Higher operating temperatures and longer dwell time require 50% larger freezer to produce the same amount of product. |

| Operational Flexibility | Smaller freezing equipment leaves more room for expansion. Simple to operate and user-friendly. Precise sizing not as critical, can operate efficiently outside of the original design parameters. |

Larger freezing equipment takes up more plant space. Less user-friendly, requires more vigilant operator. Freezer must be sized precisely for a specific product and throughput. |

*The actual value depends on the pressure of the gas, the type of freezer, the freezer’s operating temperature, and other factors.